"Indium", a silvery-white and slightly bluish metal in the nature, is soft, ductile and corrosion resistant. It has the advantages of low resistance, good light permeability and strong electrical conductivity. Nowadays, Indium Tin Oxide (ITO) has been widely used in the production of LCDs, flat screens, touch screens, and optical film amongst others.

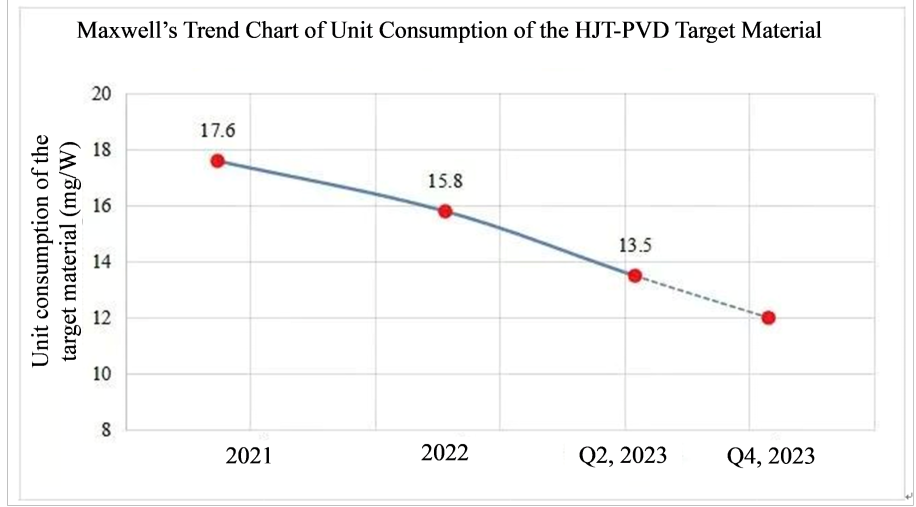

In addition, it is also used in the third step to manufacture heterojunction (HJT) cells. Specifically, through the Physical Vapor Deposition(PVD)equipment, the target material ITO becomes deposited onto the surface of silicon wafers through magnetron sputtering, and then transparent conductive oxide (TCO) films with the two sides consistent are produced.

However, the price of indium is relatively high as it is one of the rate metals. Therefore, Maxwell takes a "multi-pronged approach" from equipment, technology, and other aspects, continuously promotes a low indium solution of HJT TCO with a view to promoting the industrial development of the HJT technology with reduced costs and increased efficiency and consuming less indium when manufacturing HJT cells. The following describes Maxwell's three approaches to reduce the consumption of indium:

I. Equipment Optimization

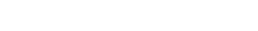

In order to optimize the PVD equipment of HJT cells, Maxwell tries to decrease the unit consumption of the target material at the very start of research and development. After continuously optimizing the sputtering unit, Maxwell's latest equipment consumes 13.5mg/W of 100% indium-based target materials per unit theoretically, dropping from nearly 20mg/W. Besides, old equipment can also be upgraded in this regard.

In the process of reducing the unit consumption of target materials, Maxwell has accumulated massive test data and improvement solutions and formed a clear and effective technical path. It is expected that Maxwell can offer overall solutions of HJT cell manufacturing with the theoretical unit consumption of 100% indium-based target material reduced to around 12mg/W by the end of 2023.

II. Low-indium Laminated Film

The combination of a low-indium laminated film solution (50% indium free) and the foregoing equipment optimization solution can help bring the theoretical unit consumption of indium-based target materials down to about 6mg/W.

After continuous technology research and development, Maxwell offers a HJT cell manufacturing solution of 50% indium-based and 50% non-indium-based laminated TCO. The conversion efficiency of this solution is equal to that of 100% indium-based TCO cells. Meanwhile, the low-indium solution is reliable and stable, and can be perfectly combined with the copper plating solution, silver-clad copper solution and other low-cost solutions.

Maxwell's PVD equipment is compatible with all these low-indium solutions and these solutions can be imported by adjusting the target material and target position. Given that there are different types of non-indium-based target materials with a huge range of resistivity, Maxwell's PVD equipment runs with multiple input modes. In this way, the sputtering of non-indium-based target materials becomes more stable.

III. Large-scale Indium Recycling

Along with the growing scale of the HJT industry, the recycling of indium materials can be further realized. As non-indium-based target materials are being widely used, the indium consumption of Gigawatt (GW) level HJT cell factories is expected to be reduced to 1mg/W.

Thanks to continuous equipment optimization and technological innovation, Maxwell has acquired much expertise in the HJT technology and is trying to find more ways to help HJT cell manufacturers decrease their cost and improve efficiency. Last August, Maxwell combined the low-indium (50%) TCO technology with copper plating busbar, and acquired the ISFH certification for 25.94% HJT cell efficiency, equal to the efficiency of 100% indium-based cells. With these three indium reducing approaches, Maxwell will foster a brighter and broader future for the HJT industry.