HJT High Efficiency Solar Cell Manufacturing Whole-line Solution

The Whole-line Solution for HJT High Efficiency Cell Manufacturing, which completely covers the four processes of HJT cell production( as shown in the figure below), is independently developed by Maxwell. Through the manufacturing process for larger, thinner and half-sized wafers, the Whole-line Solution combines innovative process route, integrated MES intelligent system to further improve the conversion efficiency, yield and production capacity of solar cells, while reducing the production cost.

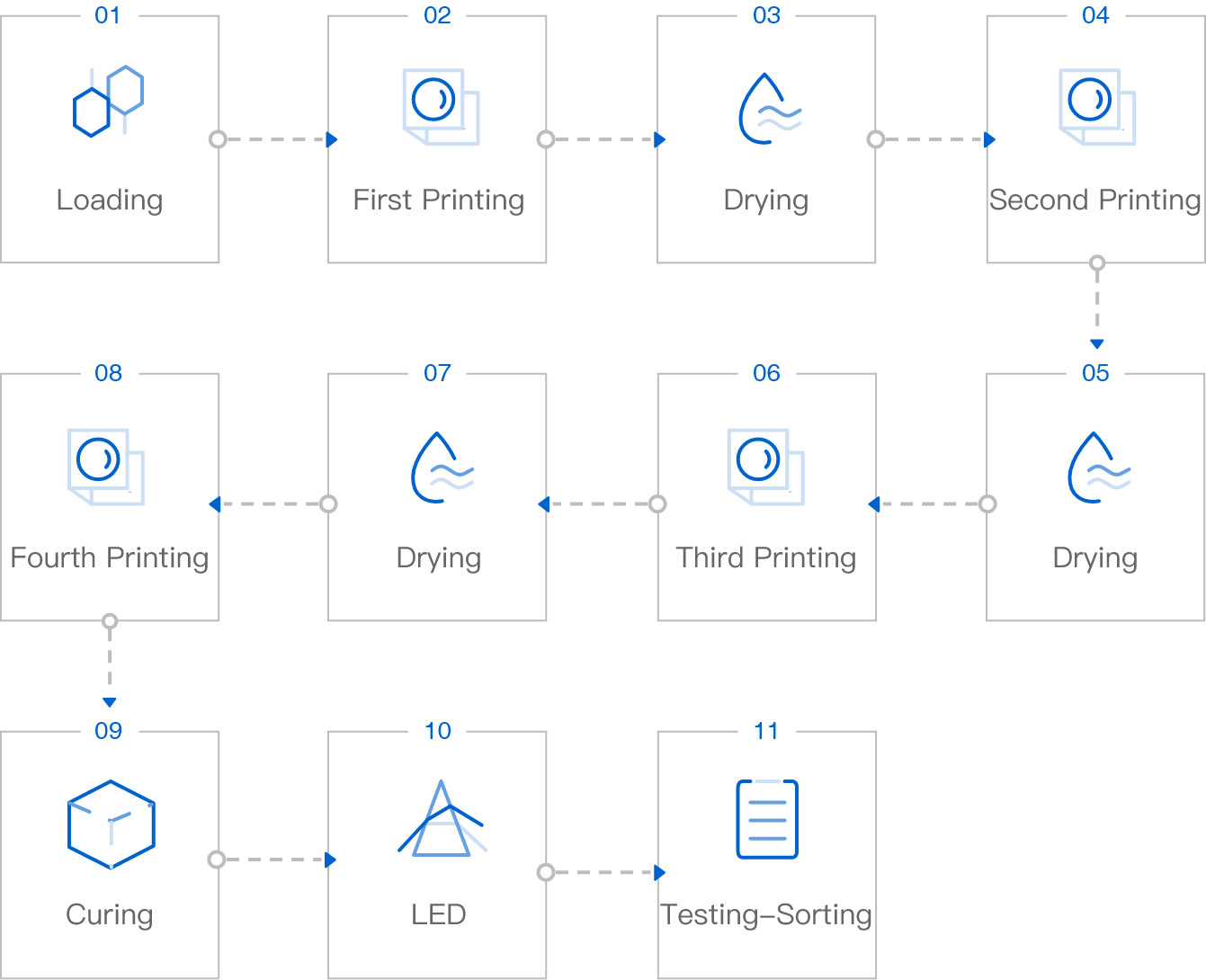

Process Flow

-

01Texturing

-

02Silicon-Based Film Deposition

(PECVD) -

03Transparent Conductive Film Deposition

(PVD) -

04Screen Printing

Advantages of the Whole-line Solution

-

TexturingEquipped with two kinds of pre-clean process:Precln#1(O?)→ ?SDE?→ ?Precln#2(H?O?)

-

PECVD EquipmentFully automatic processes for double-sided coating, continuous coating and RPS self-cleaning, with high production capacity and no need of overhead crane

-

PVD EquipmentContinuous complete the TCO coating of frontside and backside coating; High production capacity, with 8 process units (PU) improving TCO coating process flexibility, no need of overhead crane, and coating utilization rate up to 80%

-

Screen Printing

EquipmentFlat curing and integrated LED light soaking -

AutomationMinimum wafer contact, environmental control, integrated on-line detection

-

Strong MES Central

Control SystemWith functions of data collection, production line monitoring, production line management & control, and statistical analysis, the system can realize mass production piece-level tracking and trace the production process of each solar cell

Process 1 Texturing

+

HJT Texturing Equipment__HJ-TEX-182/210

In this equipment, the surface of silicon wafer is etched

into pyramid texture structure with acid and alkali liquid, and then cleaned and dried.

into pyramid texture structure with acid and alkali liquid, and then cleaned and dried.

Equipment Parameters

Equipment Advantages

-

Compatible with different kinds of wafers; with large capacity and full customization

-

Excellent process controllability, with ( Feed and Bleed Mode )

-

Strict internal environment control (acid- alkali isolation, FFU, static?electricity elimination, etc.)

-

Complete data collection (Lot Log, ID tracking, recording curve, etc.)

Process Flow

Others

A complete set of rework cleaning machine, chain type cleaning machine can be provided according to customer demand.

Process 2 PECVD

+

PECVD Coating Equipment__Maxwell MV-LH06

A set of inline non-stop PECVD coating equipment, depositing I layer & doping amorphous silicon film/microcrystalline silicon film on front & backside of wafer

Equipment Parameters

Equipment Advantages

-

Inline multi chamber quasi dynamic PECVD coating technique

-

Layered high quality amorphous silicon passivation coating technology

-

PECVD multilayer showerhead discharge cathode design

-

Composite tray design with large size, light load, low thermal expansion coefficient and high flatness

-

Inline corrosion resistant magnetic fluid & vacuum transfer for large size tray

-

RF quick ignition setting and real-time plasma glow monitoring

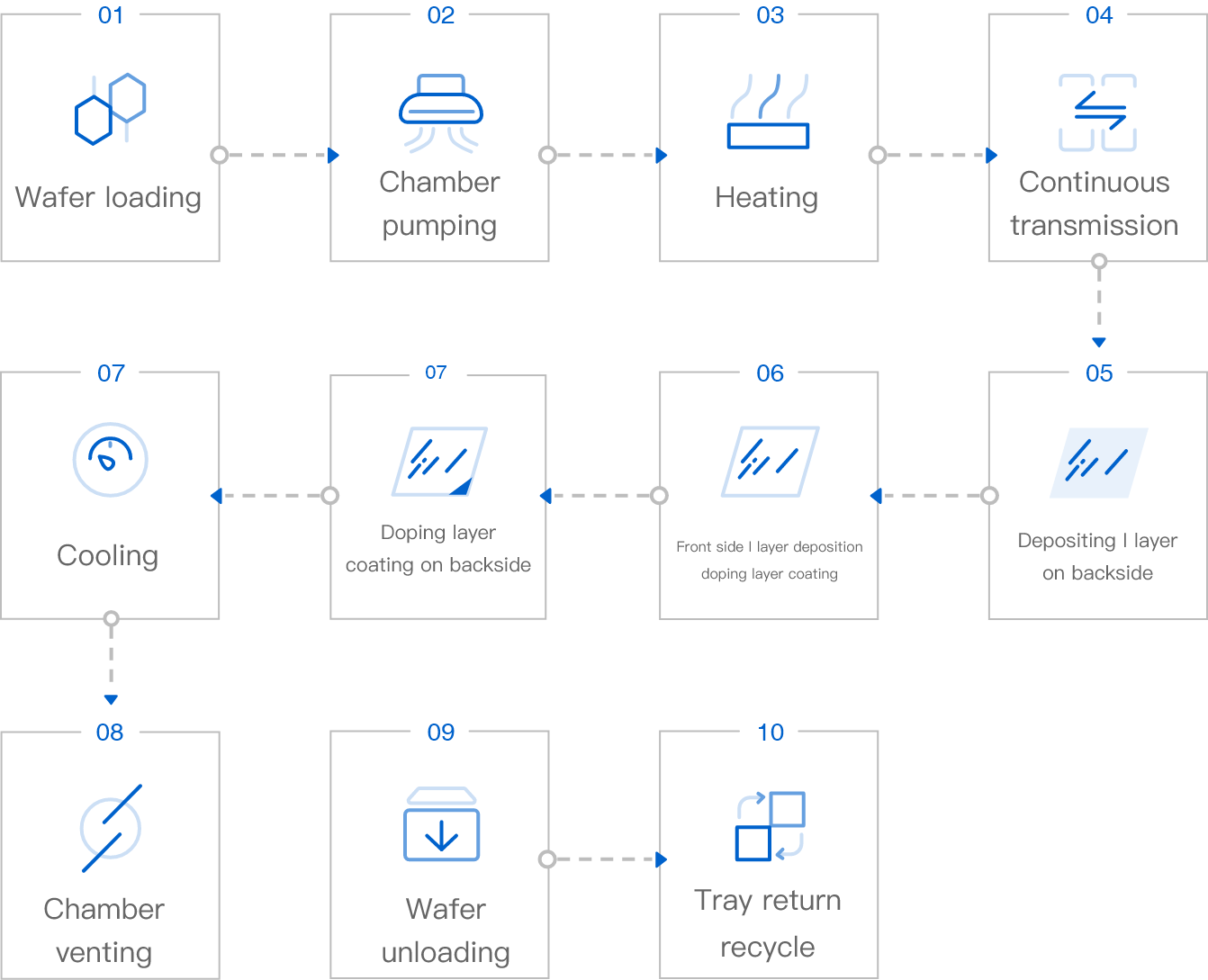

Process Flow

Process 3 PVD

+

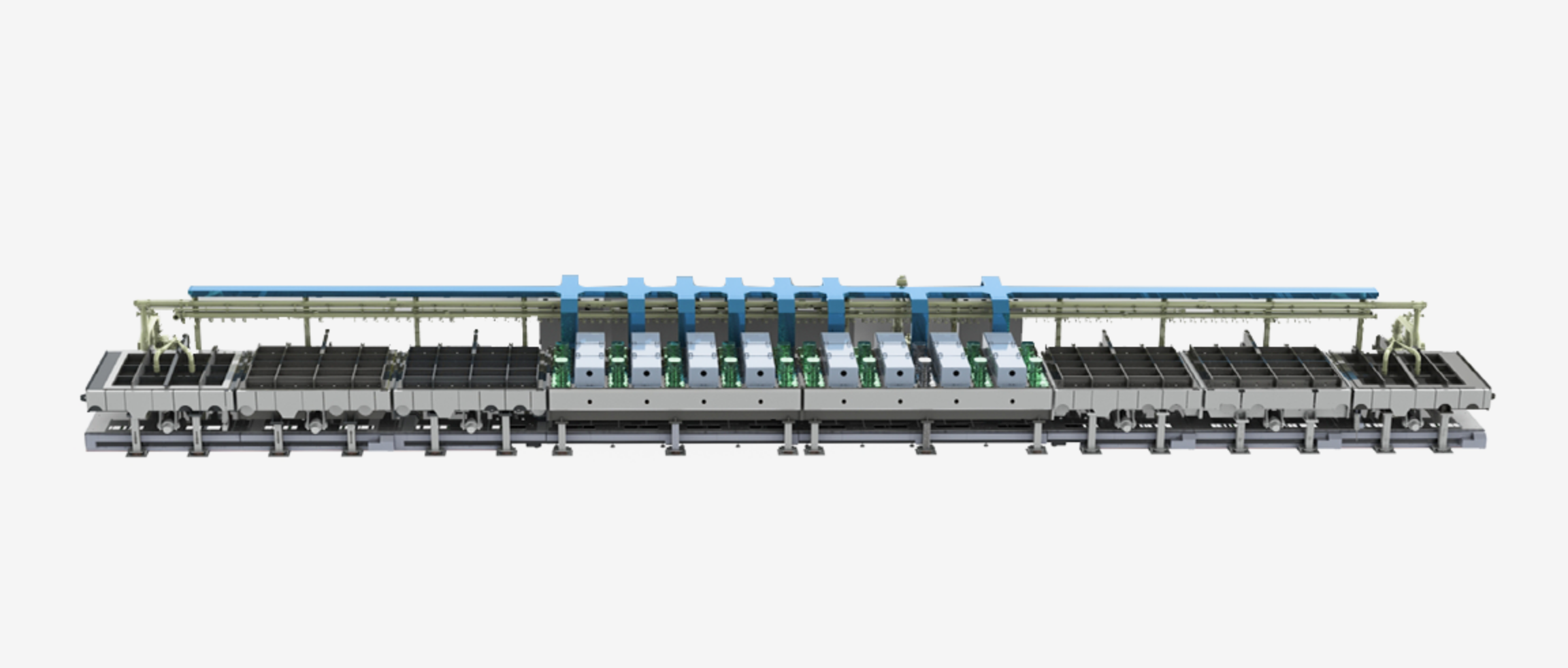

HJT PVD Equipment__Maxwell P6

A set of horizontal on-line magnetron sputtering continuous coating equipment, with capability of simultaneously double-sided coating.

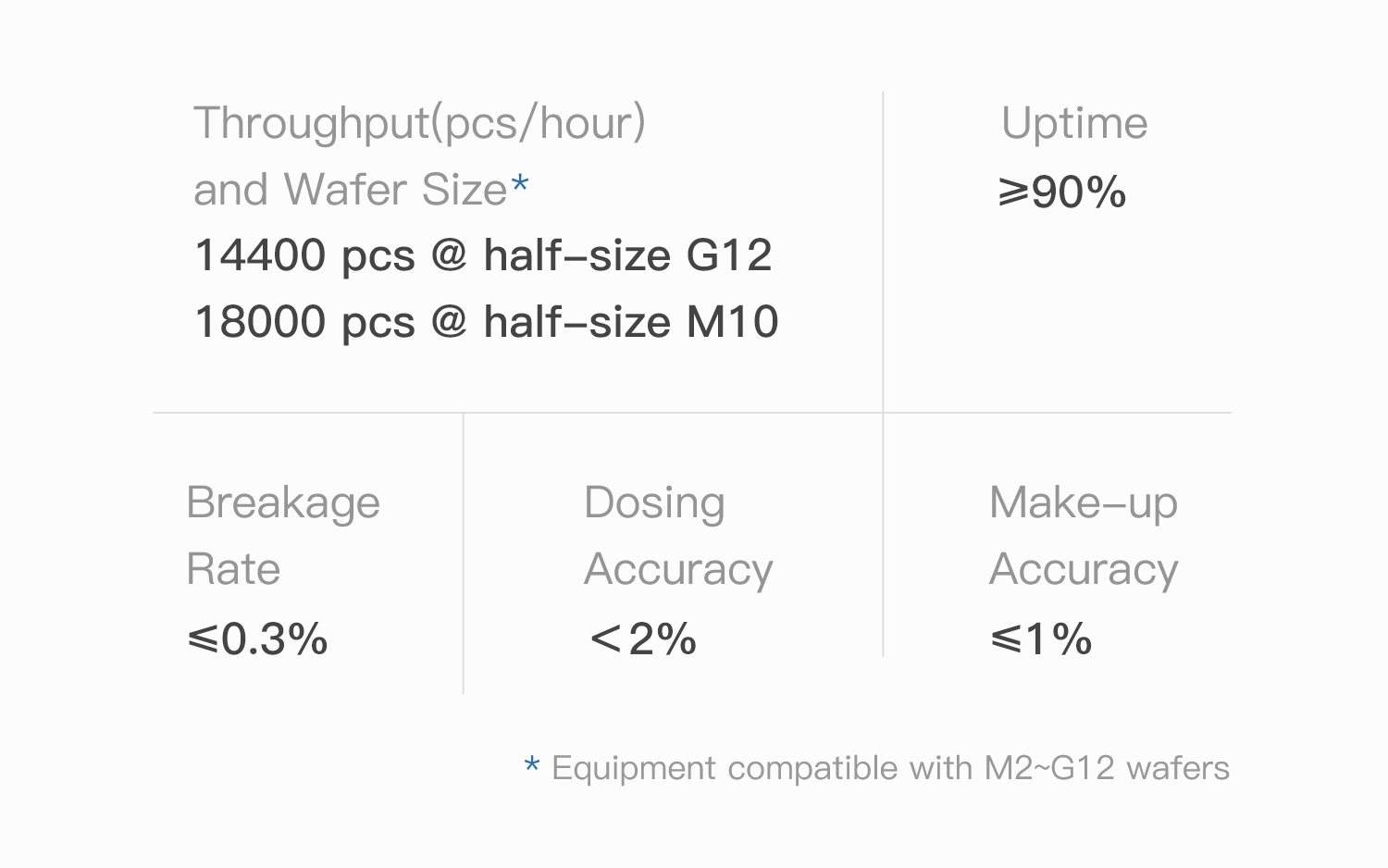

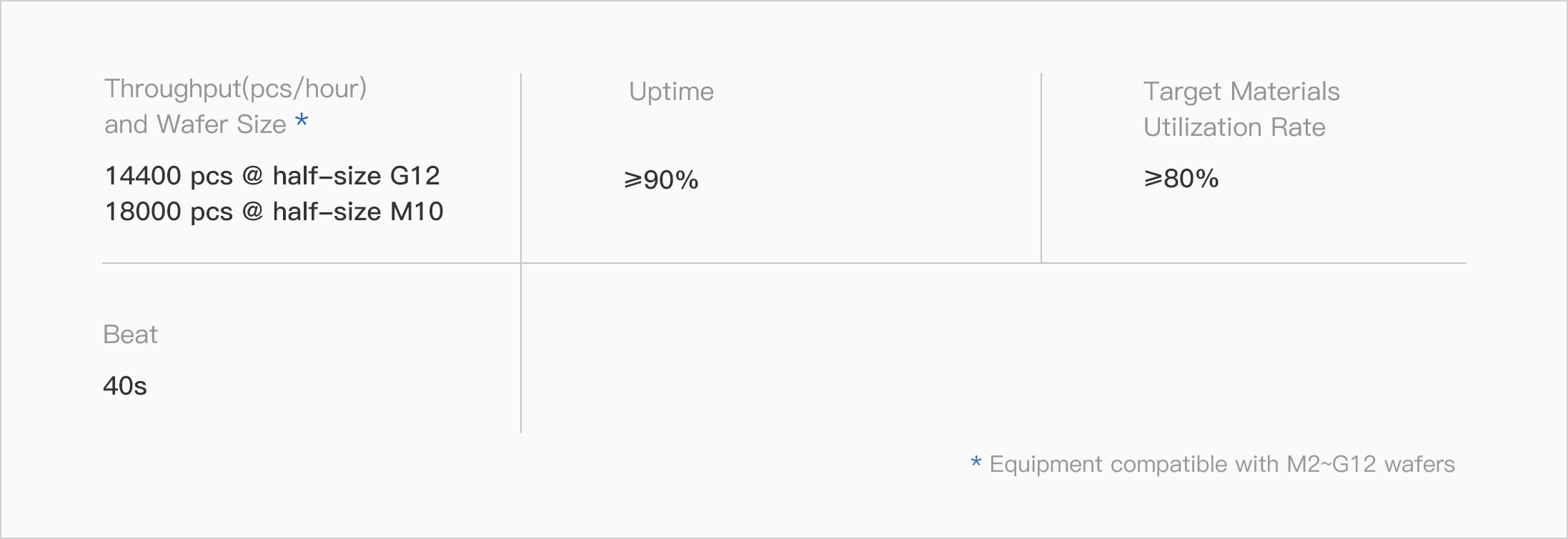

Equipment Parameters

Equipment Advantages

-

Maximum Capacity(14400pcs@ half-size G12, 600mw for single equipment)

-

Composite structural tray design with large size, light load, low thermal expansion coefficient and high flatness specially for PVD coating of HJT cell

-

Design of PVD cavity structure with high productivity and low debris rate for HJT cell

-

PVD cathode structure design of high magnetism, low temperature and high sputtering rate

-

Design of fast and uniform heating unit

-

Design of PVD cathode cavity with good uniformity

-

High-quality TCO film coating technology with short CT for PVD online

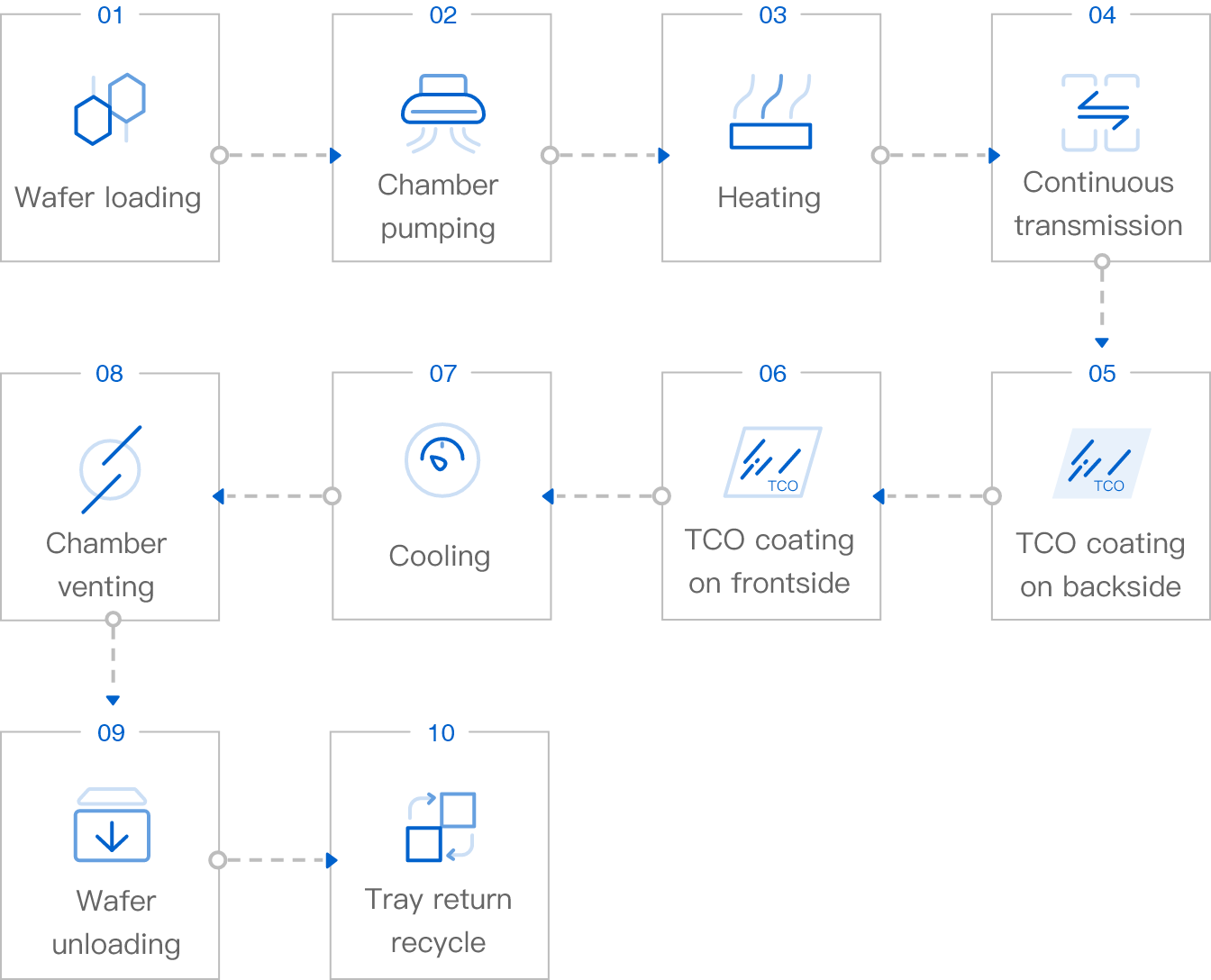

Process Flow

Process 4 Screen Printing

+

The Complete Line of Screen Printing Equipment for HJT Cell

MW-XDL-DP(HJT)

MW-XDL-DP(HJT)

The equipment is utilized for screen printing test, curing and LED of the HJT cell.

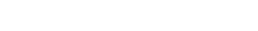

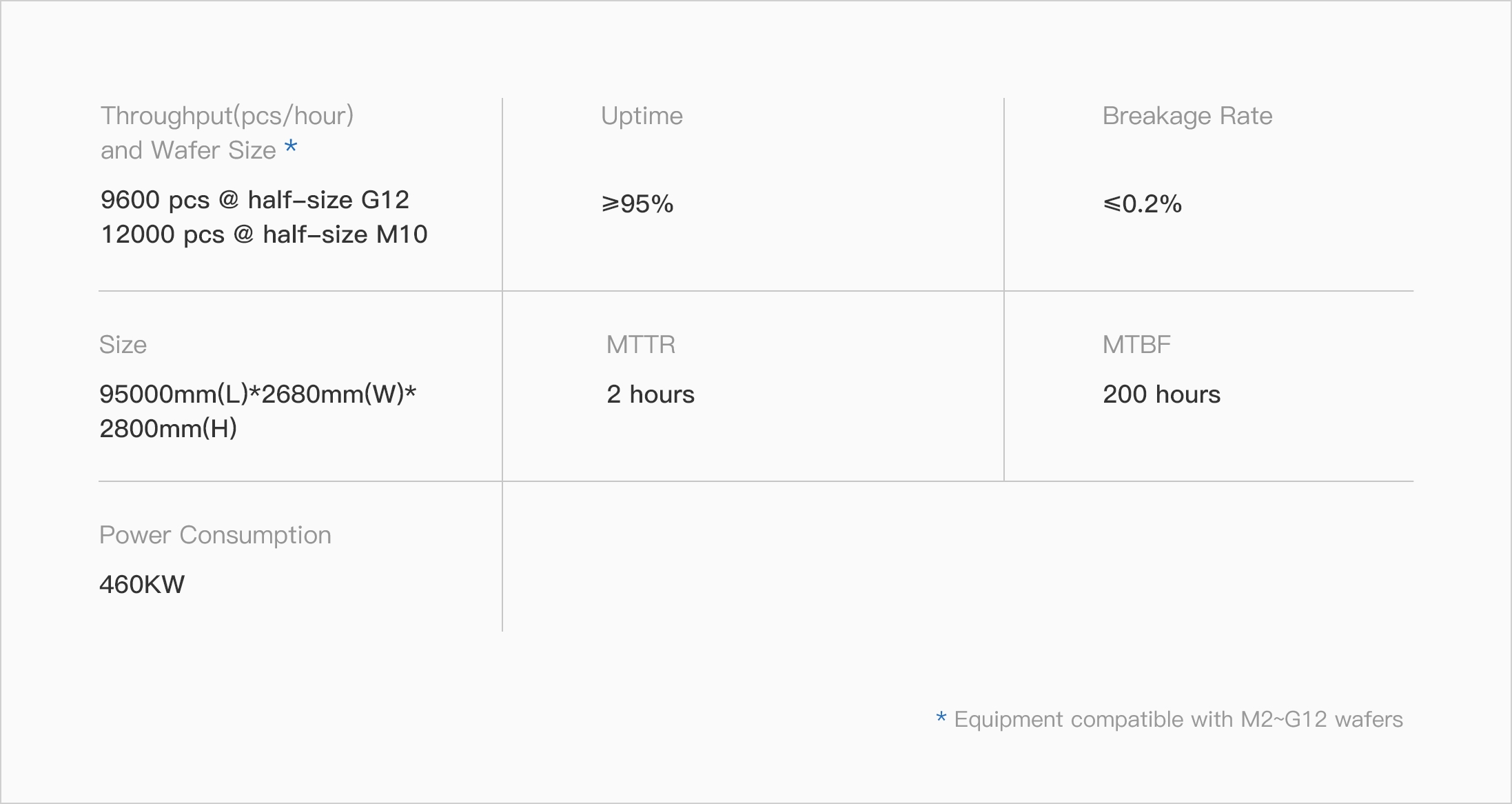

Equipment Parameters

Equipment Advantages

-

Compatible with MES, UPS and RFID functions

-

High accuracy and large capacity equipment compatible with half-cell

-

Equipped with unmanned automation for the whole line

-

Whole line made by Maxwell, even the testing devices

Process Flow